The unmatched precision of the Mitutoyo Coordinate Measuring Machine solutions help you achieve faster, more accurate inspection and quality assurance. Our CMMs are suited for up to five-axis measuring and three-dimensional tolerances in a wide array of contact and non-contact applications. For applications like factory intelligence and advanced manufacturing, Mitutoyo coordinate measuring machines integrate seamlessly while delivering the reliable precision you need.

Benefits of a Mitutoyo Coordinate Measuring Machine

We bring our industry-leading expertise and commitment to innovation to each coordinate measurement machine solution we produce, enabling higher accuracy, improving efficiency — and helping you keep pace with today's production demands.

Advanced Digital Control

Our coordinate measuring machine solutions deliver precisely controlled coordinate positioning, movement and speed for maximum measuring performance.

Multiple Sensor Support

Our coordinate measuring machine solutions can be used with a wide range of contact and non-contact sensors: single-point, active scanning, five-axis, laser, optical, surface finish and more.

Smooth, Precise Movements

Our coordinate measuring machine solutions have self-adjusting air bearings on all axes to make movements smooth, quick and precise — delivering the accuracy you need.

Thermal Compensation

Sophisticated sensors detect and correct for temperature variations in real time. This provides a level of coordinate measurement machine accuracy that typically requires a thermally controlled room.

High-Accuracy Construction

Our bridge-type coordinate measuring machines are designed using a finite element method (FEM) analysis that makes guideways straighter and more rigid. This also ensures effective vibration dampening.

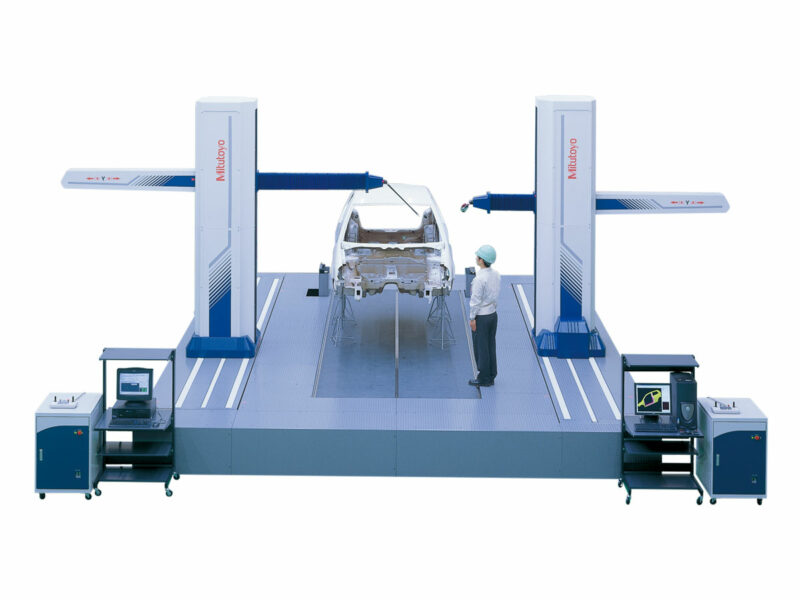

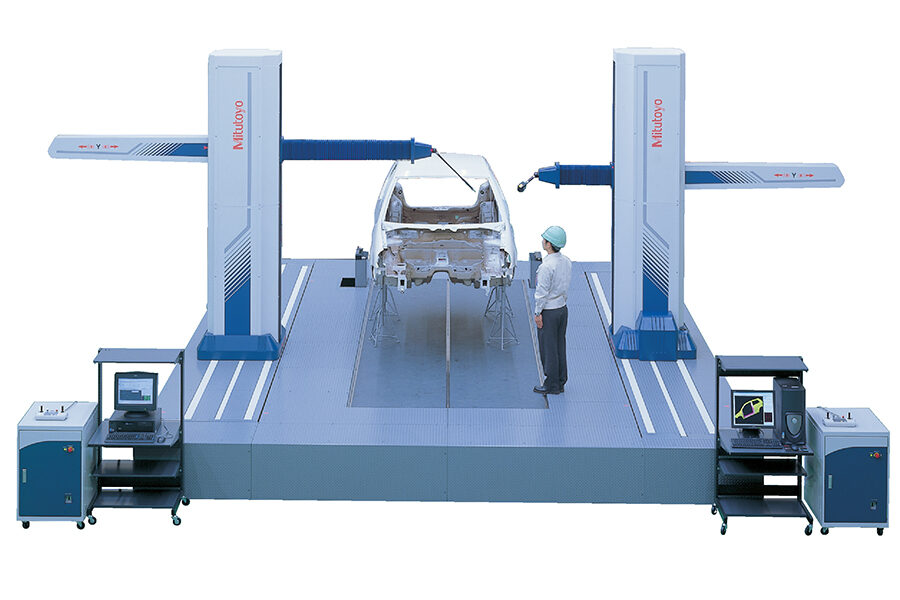

Large Heavy Duty Machines

Separate guide bridge-type coordinate measuring machines designed to be used for measuring large, heavy workpieces with high accuracy and drive speed equipped with a system to automatically restore accuracy deterioration (MOVAC) caused by foundation deformation as a standard feature.

CMM Options for Every Application

Mitutoyo CMMs use our global metrology software for measuring with or without a CAD model for automatic part program generation

The High-Accuracy series with high-moving speed and acceleration is achieved with improved rigid air bearings on all guideways

The Ultra-High accuracy series with a fixed bridge structure with superior stability of motion for world class measuring accuracy

The Shop Floor series CMMs are flexible measurement systems with high-throughput measurements for in-line or near line applications

The CARB series CMMs are suitable for extra-large-sized workpieces for aerospace, heavy equipment and automotive

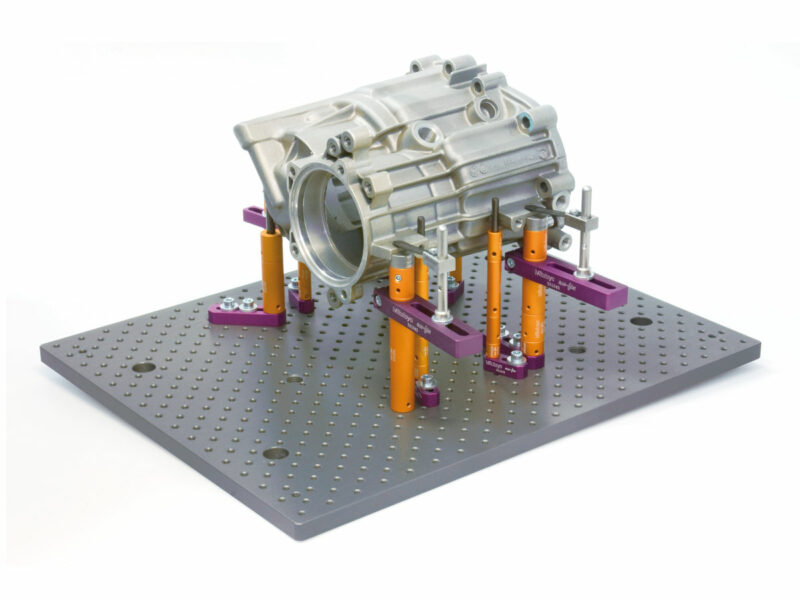

Take full advantage of your Mitutoyo CMMs with a variety of contact & non-contact probes

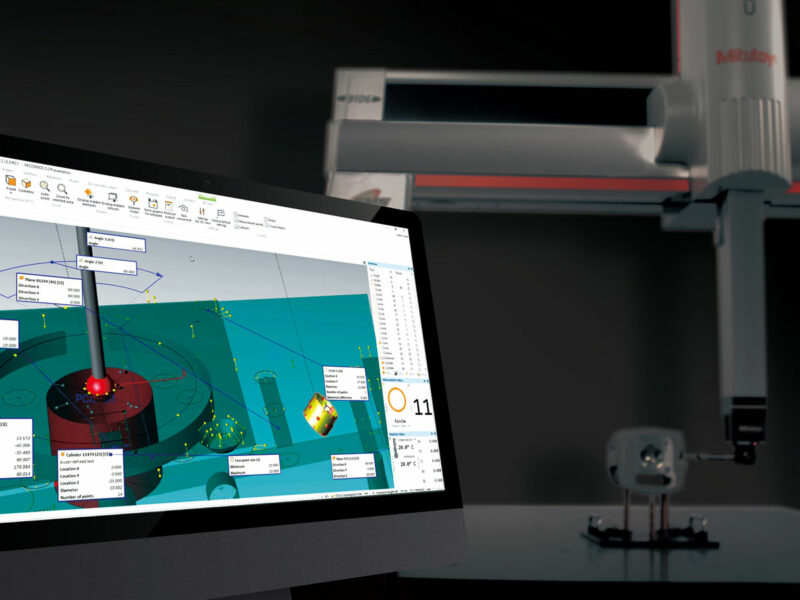

Measure with or without a CAD model for automatic part program generation and modules for application specific programming, analysis tools

Accessories such as fixturing, styli, verification artifacts, rotary and indexing tables all make your CMM more versatile & powerful

With a complete range of in-line and near-line coordinate measuring machines, Mitutoyo delivers exceptional durability, speed and accuracy for factory-floor applications of nearly any shape, size and space.

CMM Software

Our customizable suite of MiCAT®, MCOSMOS® and MSURF® integrated software solutions easily creates measurement plans and reports results for a variety of applications, from basic geometry measurement to the digitizing of complex profiles and 3D surfaces.

Resources

Our resource library is your one-stop shop for the metrology, measurement and quality assurance information you need to improve your business.

Installation and Integration

The metrology experts at Mitutoyo can help incorporate your CMM solution into your manufacturing processes, as well as delivering service and support throughout the lifecycle of your solution.