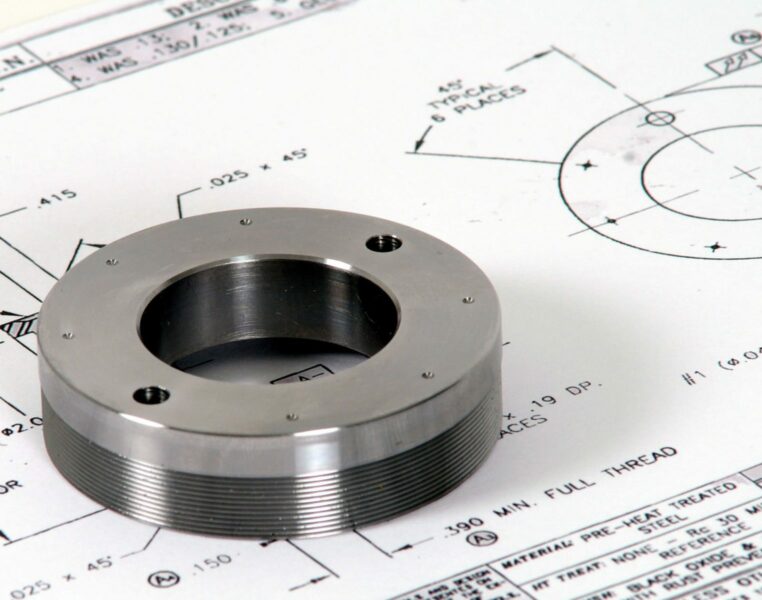

Select from contact and non-contact probes for scanning, optical, laser, and tactile measuring as well as surface roughness probe to take full advantage of your Mitutoyo Coordinate Measuring Machines.

Support for CMM Precision

Mitutoyo CMMs are powered by our global metrology analysis software. Our range of accessories also includes probe systems, change racks and non-contact CMM probes designed to power our CMM parts for a wide range of applications on the production line.

Product Series

CMM probe heads support a variety of probe sensors for manual and CNC CMMs

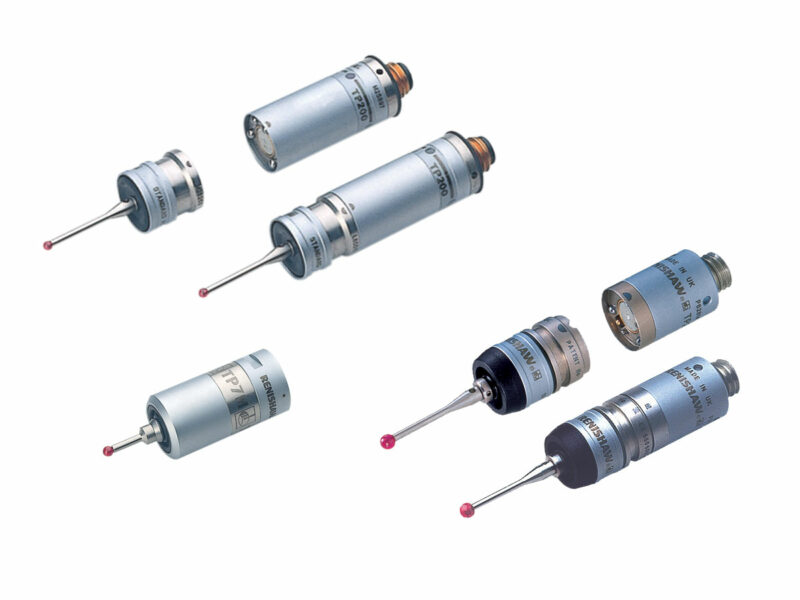

Tactile probes take individual point measurements using various touch technologies

Scanning probes acquire hundreds of surface points per second for form, size and position measurements

Measure surface roughness with a CMM with high accuracy

Laser probes automatically adjusts to workpiece surface characteristics to deliver highly efficient measurement

The QVP probe provides image measuring capabilities for Coordinate Measuring Machines

Simultaneous 2-axis and 3-axis scanning capabilities for accurate, ultra-high CMM measuring speeds

Exchange probe sensors automatically reducing CMM measurement times

Our A2LA-accredited calibration lab offers the broadest scope of any commercial lab in the country, with masters calibrated directly at NIST.

With service and support available through the lifecycle of your CMM solutions, Mitutoyo is your true metrology partner.

Our resource library is your one-stop shop for the metrology, measurement and quality assurance information you need to improve your business.

Manufacturers in countless industries trust Mitutoyo for reliable, high-performance metrology solutions. See what we can offer your industry.