Our reference gages are designed to help your metrology instruments maintain the industry-leading level of precision you expect from Mitutoyo. These solutions provide reliable, fully traceable accuracy checking and calibration across a number of requirements: length, height, straightness, thickness and many more.

Benefits of Mitutoyo Reference Gages

Reliable accuracy checking is an essential part of the dimensional quality control process, and our fully traceable reference gages are the ideal solution. No matter which reference gage you select, your inspections and calibrations can meet the highest quality standards.

Full Traceability

Our gage blocks and other reference gages are fully traceable to relevant industry standards, giving you the tools needed to measure and calibrate with confidence.

High Accuracy

We use an advanced lapping technique to ensure our reference gages maintain optimal flatness and surface roughness levels.

Durable Design

Many of our reference gages are available in both steel and ceramic models, offering improved corrosion resistance and dimensional stability.

Versatile Applications

From inspecting precision hand tools and optical instruments to comparing gage blocks against a confirmed standard, the potential uses of our reference gages are practically endless.

Explore Our Reference Gage Solutions

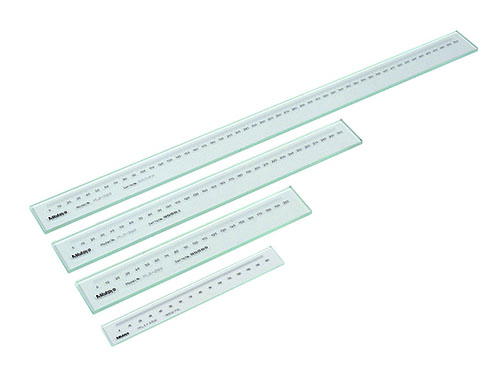

Mitutoyo offers a complete selection of gage blocks available in different sizes and materials in inch or metric

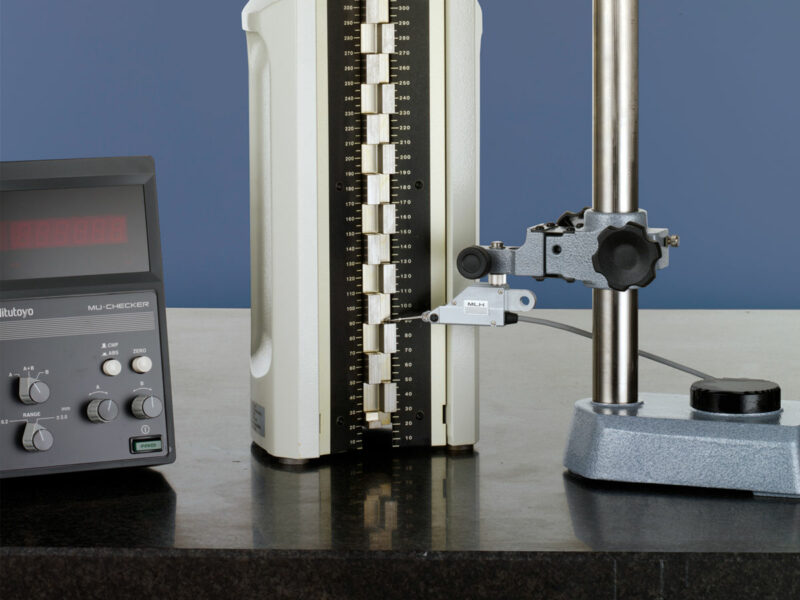

Accurately measure height, squareness or straightness with the Mitutoyo series of measuring tools

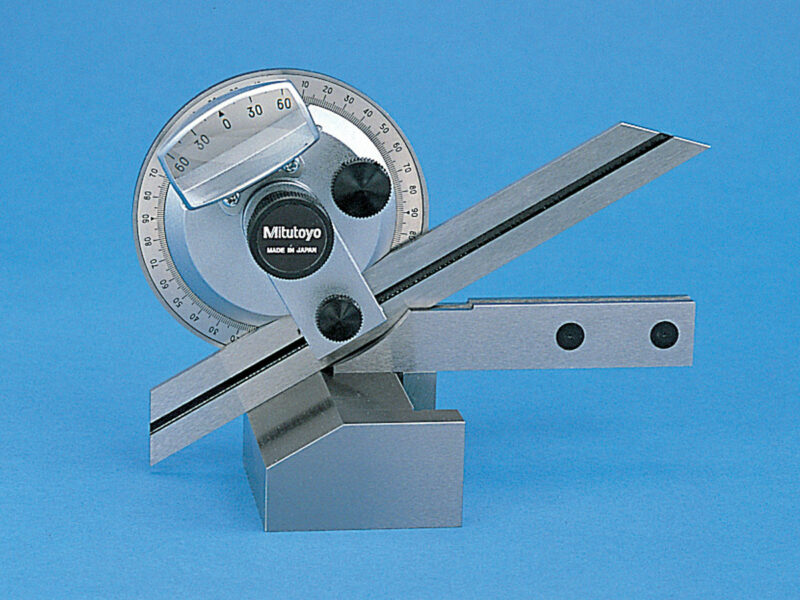

Mitutoyo reference gages provide reliable accuracy checking and calibration for a number of dimensions

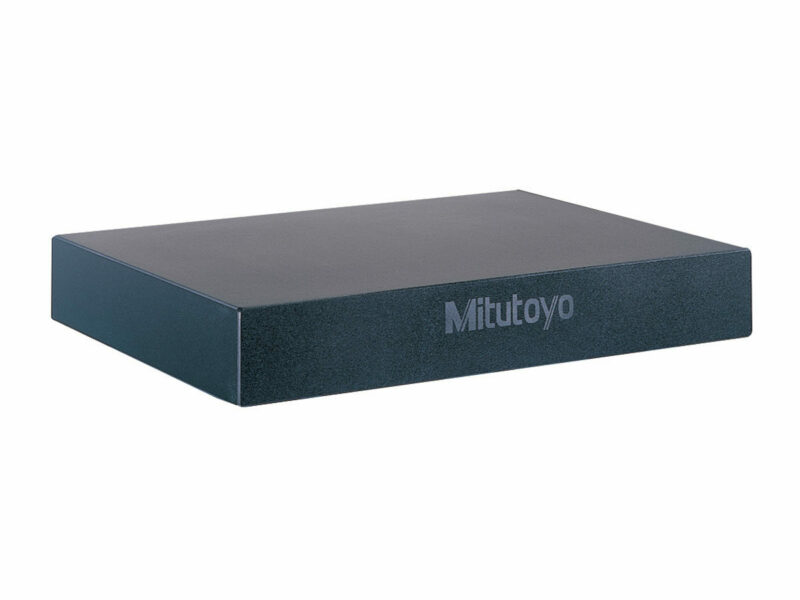

Mitutoyo Black Granite Surface plates are free from burrs, protrusions, rust, and wringing, making them ideal for precision measurement platforms